- Husqvarna

Купи на изплащане със стоков кредит от Банка ДСК

• Улеснена процедура за електронно подписване

• Атрактивни условия по кредита

• Параметри изцяло по Ваш избор

• Одобрение до няколко минути изцяло онлайн

Engine

The TX 300 engine is at the pinnacle of 2-stroke performance and weighs just 23.9 kg. Expertly assembled with the latest technical innovations, the TX 300 features electronic fuel injection (EFI) and an electronic exhaust control for lower running costs and improved reliability. Configured with no separate oil tank, pre-mixed fuel is required, which is identical to the motocross models. A proven e-start adds to the simplicity of this popular model and guarantees fast starting in all conditions.

Cylinder

The cylinder features a 72 mm bore and an electronic exhaust control system. This highly innovative technology manages the opening of the lateral exhaust ports before the main exhaust ports open to deliver strong, controllable power. The upper contour of the exhaust port features a machined finish for improved port timing and unrivalled performance.

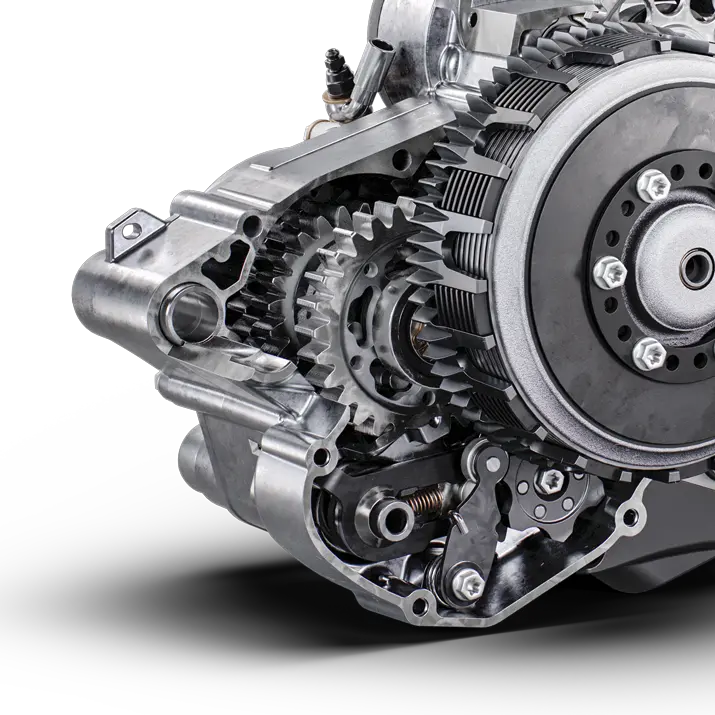

Crankcase

High-pressure die cast production processes allow for the crankcases to be manufactured with a thinner wall thickness to keep the overall weight to a minimum and to position the shaft arrangements in the perfect position for optimised mass centralisation. This clever design aids the overall balance and agility of the TX 300 while redesigned, symmetrical engine mounts further improve flex characteristics.

Crankshaft

Designed with weight reduction and performance in mind, the crankshaft in the TX 300 engine improves throttle response and contributes to the lightweight feel of the motorcycle. The perfect balance of rotating masses is achieved by balancing the weights of the crankshaft flywheel and the rotor, and thanks to the innovative counter balancer shaft, engine vibration is kept to an absolute minimum.

Counter balancer shaft

The TX 300 features an innovative laterally mounted counter balancer shaft. This shaft significantly reduces engine vibration, resulting in a smoother and more comfortable ride.

DDS clutch

The TX 300 features a dampened diaphragm steel (DDS) clutch, which includes a single-diaphragm steel pressure plate instead of traditional coil springs. It integrates a damping system for better traction and durability. The clutch basket is a single-piece CNC-machined steel component and allows the use of thin steel liners that contribute to the compact design of the engine.

Gearbox

The 6-speed gearbox is manufactured exclusively by Pankl Racing Systems and ensures the highest level of durability and reliability. The shift drum and shift fork are designed to improve leverage, which ensures significantly smoother and more precise shifting.

FRAME

For 2025, material has been reduced or removed around the steering head and shock mount, which lowers the weight of the frame by 300 g. In addition, this improves handling, particularly on the approach to corners, without sacrificing straight-line stability. A premium metallic blue powder coating is applied to the frame with protectors offering superior protection, durability, and grip in all conditions.

Polyamide-reinforced aluminium subframe

Made from 60% polyamide and 40% aluminium, the two-piece subframe ensures exceptional strength and durability at an overall weight of just 1.8 kg. The lower subframe spars and frame mounts are manufactured from cast aluminium for strength at the lowest possible weight. Injection-molded polyamide is used to construct the upper section of the subframe to enable specific flex characteristics.

Triple clamps

Working in unison with the frame design and suspension set-up, the CNC-machined triple clamps endure precisely calculated geometry for increased stability. Handlebar flex can be customised with the handlebar clamp, which offers two mounting options - rubber-damped for less vibration, or fixed for enhanced front-end feedback. The upper triple clamp is stiffer to ensure a smoother fork action and plays a vital role in the perfect alignment of the front wheel for superior handling.

WP XACT front suspension

Rigorously tested by WP's research and development department, the 48 mm WP XACT closed cartridge spring forks fitted to the TX 300 provide exceptional comfort. For 2025, the settings are updated to suit the new frame and linkage revisions. Inside the forks, mid-valve pistons optimise oil flow and prevent foaming for consistent and predictable damping at all times. A hydrostop, active in the final 68 mm of travel, reduces the impact of harsh and high-speed landings for continued straight line stability and forward momentum. Both the compression and rebound settings can be quickly adjusted by hand using the easy access clickers.

WP XACT rear suspension

Inside the WP XACT rear shock is a Computational Fluid Dynamics (CFD) optimised main piston for superior initial comfort and to provide strong hold-up in all conditions. Updated for 2025, the linkage features new, lower friction seals while a smaller diameter linkage bolt reduces weight. The standard rebound and high and low speed compression settings have been adapted to suit the new frame and can be easily adjusted by hand to create a personalised set-up.

Swingarm

The swingarm is manufactured using a die-cast production process for optimal rigidity. To optimise and match the flex characteristics of the chassis, a 22 mm rear axle is utilised. For 2025, the machining of the swingarm helps to improve the durability of the new chain slider.

Bodywork

The bodywork has been designed so riders can perform at their very best for extended periods of time. Following countless hours of testing and refinements, the large contact points and surfaces in the rider triangle enhance grip on the machine, which helps to reduce fatigue. New tank shrouds complement the progressive look of the bodywork while a sightly taller and wider seat allows for complete freedom of movement on the motorcycle. A high grip cover ensures riders stay firmly in place under hard acceleration.

Airbox

A stronger, one-piece airbox design with an optimised air intake reduces air deformation, ensuring an unrestricted flow of air and maximum filter protection. The Twin Air filter is easily accessed without tools, by simply removing the left side panel for easy maintenance.

Hydraulic clutch

The high-performance Brembo hydraulic clutch system guarantees even wear, near maintenance-free operation, and perfect action in every condition. With this hydraulic system, free play is constantly compensated so that the pressure point and function of the clutch remain identical in cold or hot conditions, as well as over time. Countless hours of race-focused testing have proven the exceptional reliability of the high-quality, Italian-made Brembo hydraulic system.

Hydraulic brakes

The highest level of quality is guaranteed as the class leading Brembo brake calipers are made from single-piece aluminium for exceptional strength at the lowest possible weight. Together with a 260 mm front and a 220 mm rear disc, which are designed to prevent mud build-up, superior stopping power and braking confidence is guaranteed in all conditions. For 2025, a new, stronger rear brake pedal offers improved durability for continued braking performance.

Protaper handlebar

Developed between Husqvarna Motorcycles and leading handlebar manufacturer ProTaper, the exclusive bend offers superior comfort, class-leading strength, and fatigue resistance at the lowest possible weight.

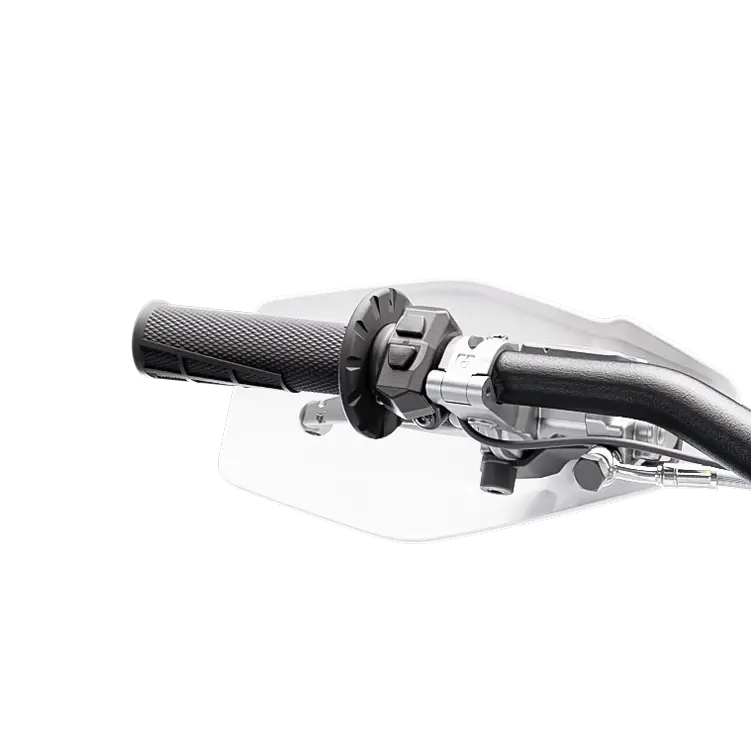

ODI grips

ODI lock-on grips feature an innovative, integrated throttle mechanism and are installed without using glue. The throttle assembly offers easy free-play adjustment with the option to fit alternative cams for a personalised throttle action.

Footrests

The CFD-designed footrests are extra wide to ensure better control of the machine while at the same time are less susceptible to hooking on deep ruts and trackside barriers. This is achieved by a narrower mounting design in the frame layout, which also helps reduce overall weight.

Wheels and tyres

CNC-machined hubs and high-strength alloy rims by D.I.D are finished in striking black. They feature laser engraved logos and are fitted with a Dunlop Geomax MX33 tyre on the front and a Dunlop Geomax AT81 tyre on the rear. This tyre combination ensures progressive cornering and superior traction across a variety of terrain.

Cooling system

Manufactured from high-strength aluminium, the radiators are designed using computational fluid dynamics (CFD) to channel air through them in the most effective way. A large centre tube through the frame reduces pressure at this point in the system for a consistent coolant flow while an internal thermostat further enhances reliability.

Fuel tank

A 8.5 litre fuel tank integrates neatly with the ergonomic bodywork and features an updated rubber cushion beneath it to protect against wear from the frame. The one-piece fuel pump and integrated filter allows the tank to be emptied further to offer an extended running time. For improved durability, the external fuel line is specifically routed to make it less exposed and susceptible to damage.

Exhaust system

Tailored specifically to the TX 300 engine using an innovative 3D design process, the header pipe ensures maximum power across the rev range. The muffler features an aluminium mounting bracket for strength at the lowest possible weight, with an advanced internal construction ensuring excellent noise damping without sacrificing performance.

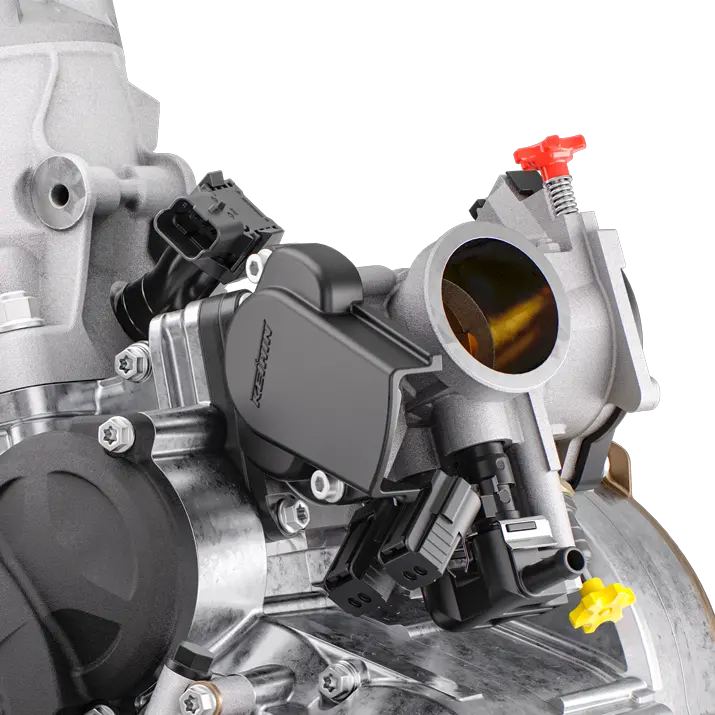

EFI

The electronic fuel injection on the TX 300 brings many benefits. The ECU from Vitesco constantly analyses the running condition of the engine and delivers the perfect air/fuel ratio at all times through the state-of-the-art 39 mm Keihin throttle body. The EFI allows a choice of two different engine maps, which can easily be activated via the handlebar-mounted switch for a personalised riding experience. Additionally, the sealing around the reed valve intake tract prevents excess fuel build up in the engine on extreme up or downhill sections for clean running at all times.

E-Start

To ensure fast starting in all conditions, the TX 300 features a highly convenient electric start. The reliable system removes the need for a kickstart completely. With the 12.8V 2 Ah Lithium-Ion battery located under the seat and close to the centre of gravity, the handling is uncompromised. The engine is easily started and stopped via the same handlebar-mounted switch for improved ease of use.

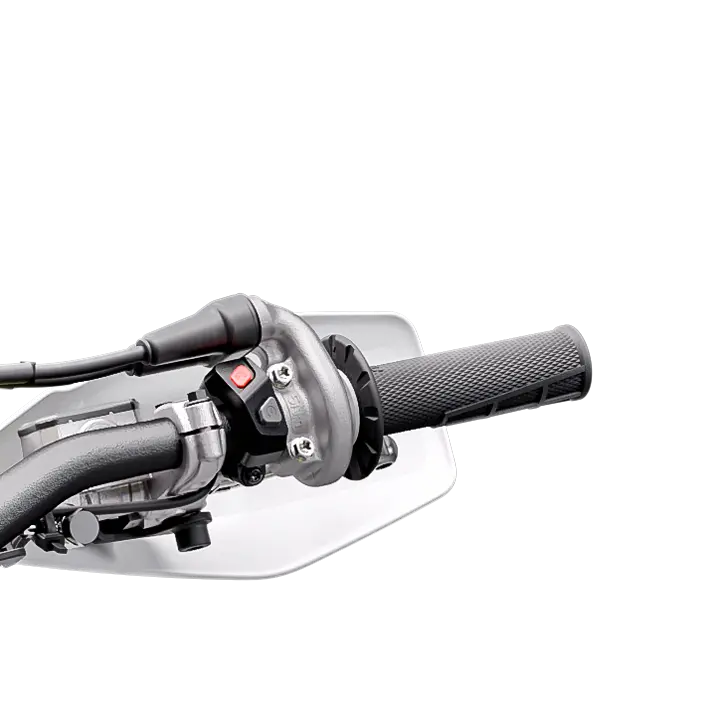

Map Select Switch

By using the Map Select Switch, the engine characteristics can be tailored to modify the power delivery according to rider preference, conditions, and terrain. It has two settings that can be safely toggled between while riding, by simply pressing a button on the handlebar-mounted Map Select Switch. Map 1 (white) is the standard option, that delivers linear, predictable power, while map 2 (green) is more aggressive with improved throttle response and sharper, explosive power output.

EMS

The engine management system (EMS) is designed to be small, light, and fast at processing data. It incorporates a rollover sensor (ROS) which cuts the ignition and shuts off the engine in the event of a severe crash for an additional layer of safety.

Hour meter

The hour meter comes with an integrated fuel level indicator, which is visible on the FI status LED, and warns the rider when the fuel level is becoming low.

Start/stop switch

The combined engine start/stop switch is located on the right side of the handlebar for easy, thumb-operated use. Not only simplifying the starting and stopping of the engine, but the removal of an additional stop only button from the handlebar reduces the risk of potential damage or activation in the event of a fall.

Radiator protection

Flame brake disc

Factory rear wheel 2.15x19"

Lock-on grip set

Plastic parts kit

ProTaper handlebar

Progressive handlebar damping system (PHDS)

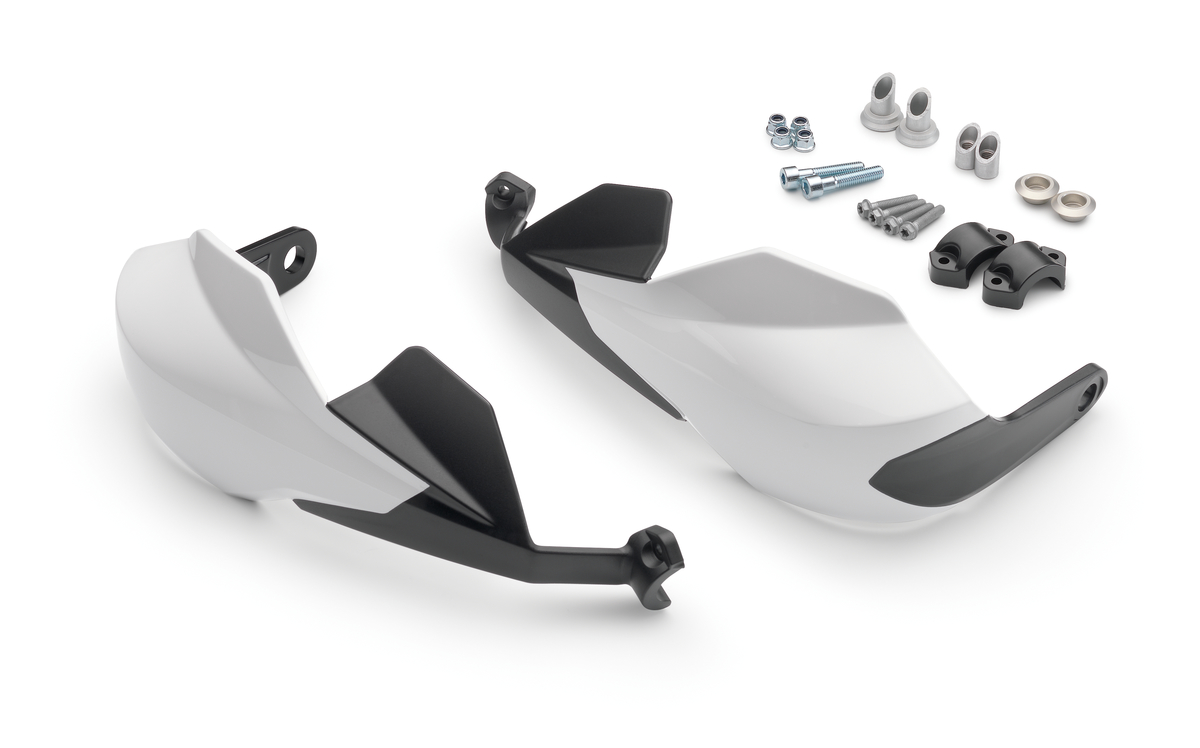

Handguard kit

Factory Racing rear wheel 2.15x18"

Factory Racing rear wheel 2.15x19"

Factory Racing front wheel 1.6x21"