- Husqvarna

Купи на изплащане със стоков кредит от Банка ДСК

• Улеснена процедура за електронно подписване

• Атрактивни условия по кредита

• Параметри изцяло по Ваш избор

• Одобрение до няколко минути изцяло онлайн

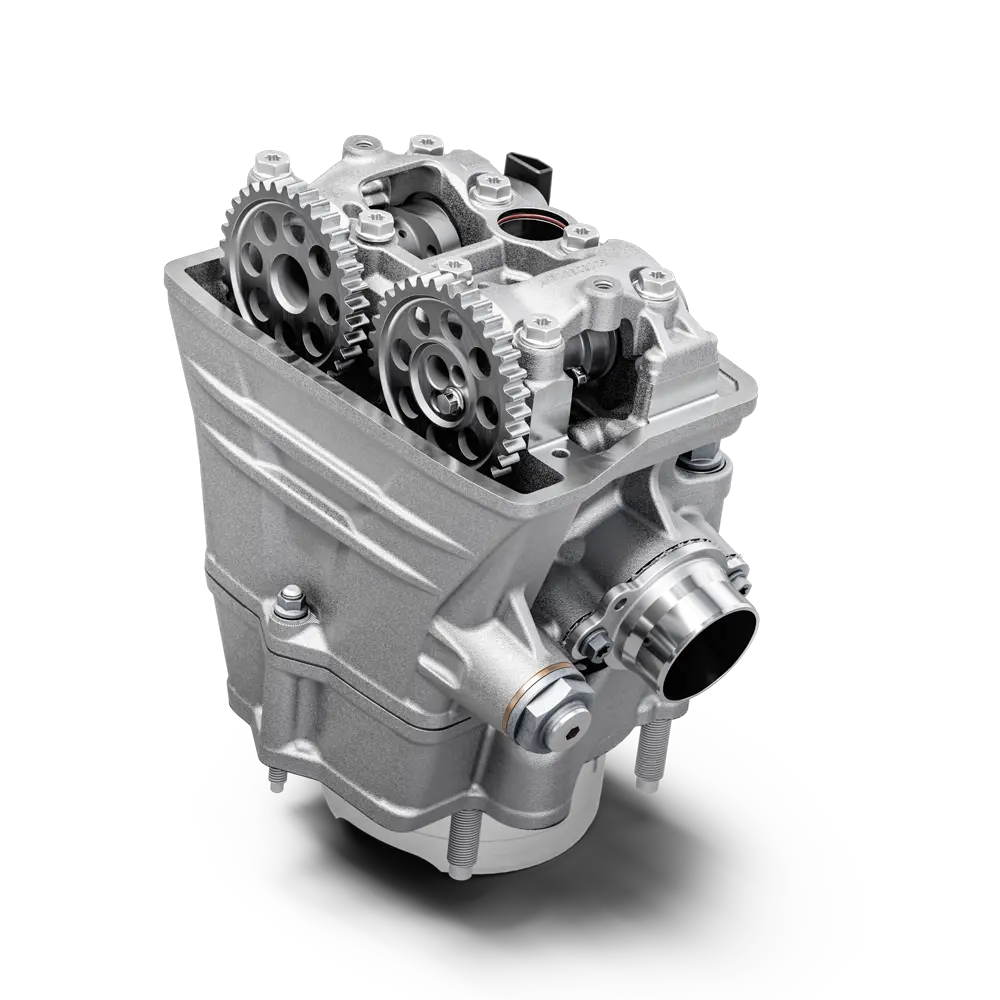

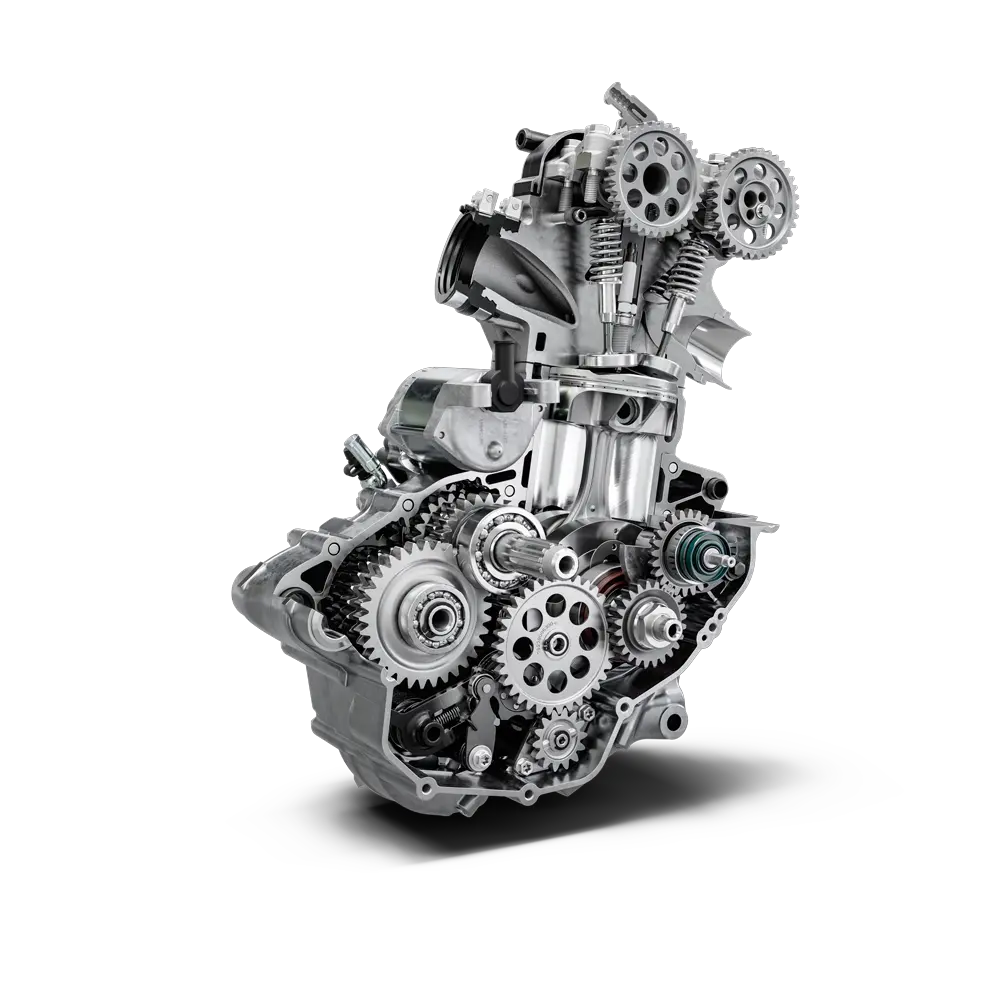

Engine

The current generation engine is designed for maximum power, which is delivered in a controllable way to suit all kinds of enduro riding. Inside, all major components and shaft arrangements are positioned close to the centre of gravity to reduce the effects of rotational inertia, which leads to agile handling. Positioned in the chassis to further centralize mass, the powerful 350 cc 4-stroke engine weighs just 28.8 kilograms.

Cylinder head

Featuring finger followers treated with a Diamond-Like Carbon (DLC) coating, the DOHC cylinder head is engineered for high-level enduro performance. For optimal gas flow, the titanium intake valves are 36.3 mm while the exhaust valves are 29.1 mm. This allows the FE 350 to rev freely and produce strong yet controllable power throughout its rev-range.

Cylinder and piston

An 88 mm bore cylinder and forged bridged-box-type CP piston combine to create a compression ratio of 13.7:1. As a result, the low oscillating mass delivers strong and controllable power. High-strength aluminium is used to manufacture both the cylinder and piston, with both components professionally engineered for outstanding performance and reliability.

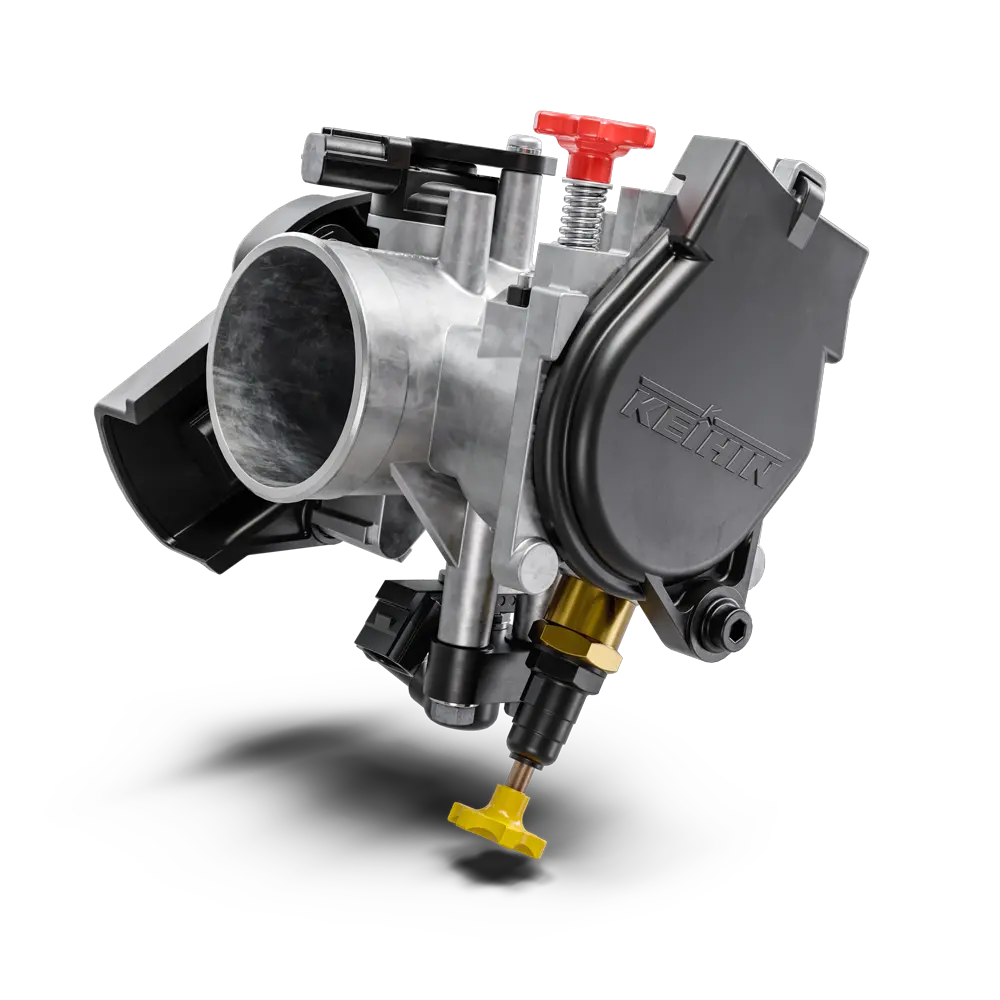

Throttle body

The FE 350 features a 42 mm Keihin throttle body optimised for throttle response. The injector is positioned to ensure the most efficient flow into the combustion chamber with the throttle cable mounted directly without a linkage for an enhanced response.

Frame

With an optimised distribution of material around the steering head and upper shock mount, the frame delivers confidence-inspiring handling and assured stability when entering corners. To complement the overall look of the machine, the chromium molybdenum chassis is finished with a premium, metallic blue powder coating. The finishing touches are the frame protectors, which not only protect the paintwork, but also provide riders with additional grip, even in the toughest conditions.

Hybrid subframe

Made from 60% polyamide and 40% aluminium, the subframe offers exceptional strength and durability at a low overall weight of just 1.8 kg. The lower subframe spars and frame mounts are manufactured from cast aluminium for reliability with the upper section made from injection-molded polyamide to enable specific flex characteristics.

Swingarm

The swingarm is manufactured using a die-cast production process and designed with a calculated level of rigidity. To further complement and optimise the flex characteristics of the chassis, a 22 mm rear wheel axle is utilised. A durable chain slider is neatly integrated into the swingarm, ensuring uninterrupted forward momentum through deeply rutted corners.

Bodywork

The ergonomic bodywork was designed to ensure that riders can perform at their best throughout every race. This was achieved through extensive testing, with the smooth contact points in the rider triangle allowing racers to grip the machine tightly with their legs, reducing fatigue. The radiator shrouds, featuring in-mould graphics, contribute to the progressive appearance of the machine, while a tall, wide seat offers unrestricted movement. A high-grip seat cover also helps keep riders securely in place under hard acceleration.

Fueltank

An 8-litre fuel tank integrates neatly with the ergonomic bodywork and features a robust rubber cushion beneath it to hold the tank in place and protect the frame from wear. For durability, the external fuel line is specifically routed to make it less exposed and susceptible to damage.

WP XACT front forks

Designed and developed for the rigours of enduro riding, the WP XACT Closed Cartridge spring forks offer consistent damping thanks to their innovative design. Inside each fork leg, lightweight springs with a polished finish enhance performance, while mid-valve pistons optimise oil flow to prevent foaming. A one-piece hydrostop, effective in the last 68 mm of travel, is highly advantageous when landing heavily as it helps to maintain forward momentum. Additionally, riders can alter the compression and rebound settings quickly and easily using the tool-free adjusters found at the top and bottom of each fork leg.

WP XACT rear shock

The WP XACT rear shock features a Computational Fluid Dynamics (CFD) optimised main piston, ensuring superior initial comfort and predictable performance in all conditions. To give riders the option of creating a personalised set-up, rebound, as well as the high and low-speed compression settings, can all be adjusted easily by hand.

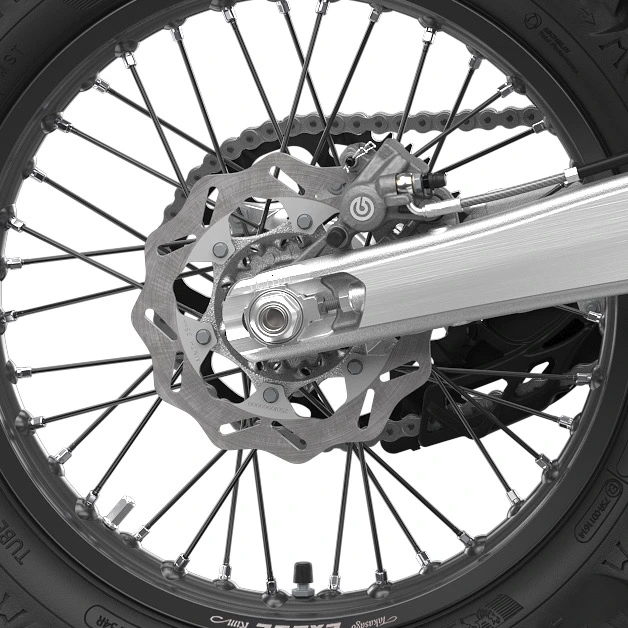

Hydraulic brakes

Class-leading Brembo brake callipers, made from single pieces of aluminium for strength, are fitted front and rear to ensure high braking performance. Together with 260 mm front and 220 mm rear discs, both designed to prevent mud build-up, effective stopping power in all conditions is assured. The strong rear brake pedal is highly durable, and less susceptible to damage when riding through deep ruts.

Hydraulic clutch

The new, high-performance Brembo hydraulic clutch system guarantees even wear, near maintenance-free operation, and perfect action in every condition. With this hydraulic system, free play is constantly compensated so that the pressure point, and the function of the clutch, remain identical in cold or hot conditions, as well as over time. Countless hours of testing have proven the reliability of the high-quality, Italian-made Brembo hydraulic system.

Wheels and tyres

CNC-machined hubs, strong spokes, and high-strength, black-anodised alloy rims are used to assemble the wheels. They are complete with the latest Michelin tyres for precise cornering and superior grip across varied terrain.

Triple clamps

The black-anodized, CNC-machined triple clamps offer premium quality as standard. They have a carefully calculated 22 mm offset and are expertly crafted using superior techniques and materials for the highest levels of quality and reliability. The handlebar clamp has a large contact surface with the ProTaper bars to help prevent twisting in the event of a crash and offers two mounting options for customisable ergonomics.

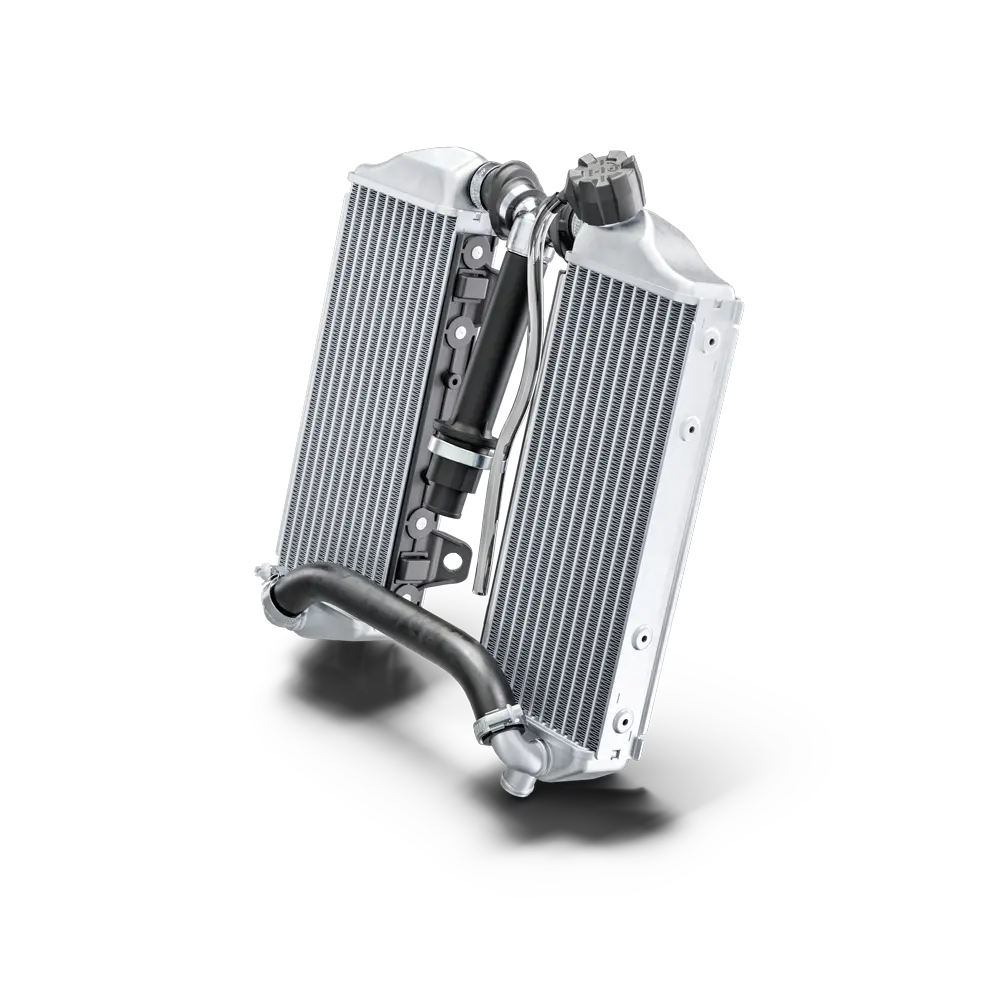

Cooling system

Manufactured from high-strength aluminium, the radiators are engineered using Computational Fluid Dynamics (CFD). The design channels air efficiently through the radiators, with a fan fitted as standard to maintain engine performance in extreme conditions. A large centre tube routed through the frame reduces pressure at this point in the system, ensuring consistent coolant flow, while an internal thermostat further improves reliability. A reliable, threaded radiator cap allows for easy inspection of the coolant level before each ride.

LED headlight

The LED headlight provides a remarkably bright light output for excellent visibility at night and is particularly effective when riding through dense woodland. A clever mounting design sees the LED lighting unit fitted inside the headlight mask using a quick-release system that allows it to be replaced quickly and easily if damaged.

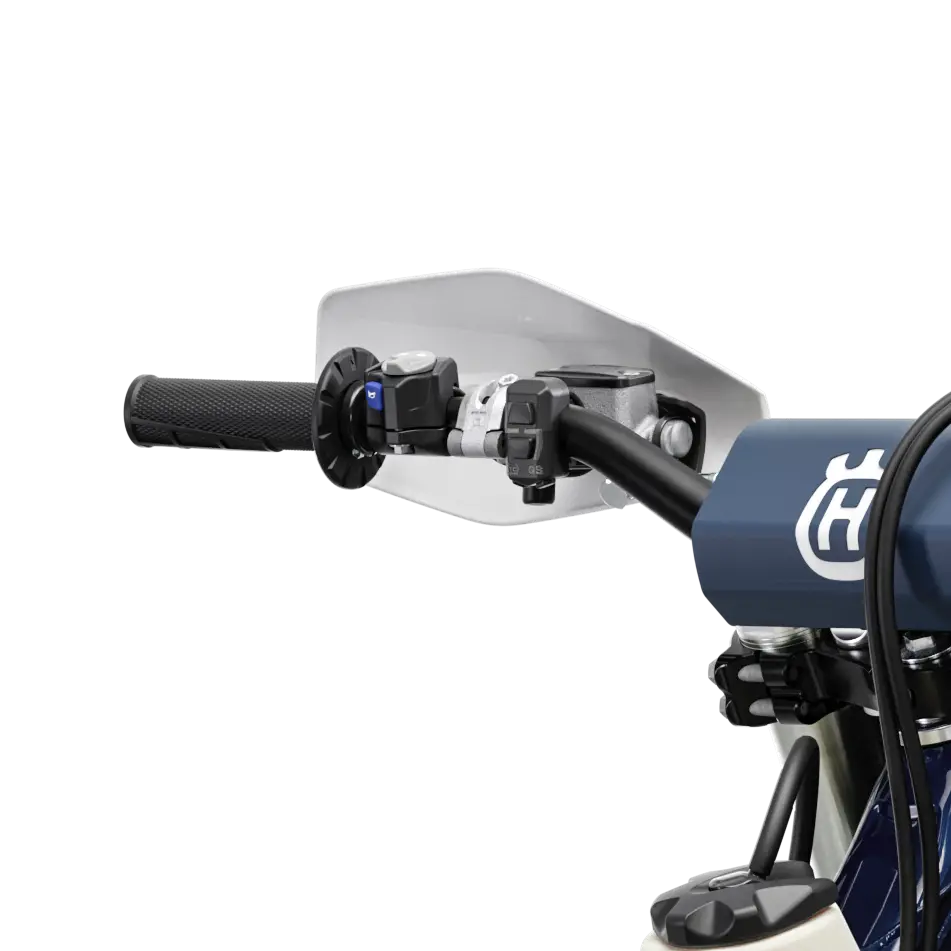

Map Select Switch

Designed for easy operation, the Map Select Switch allows riders to easily choose between two EFI maps, activates Traction Control, and engages the Quickshifter. Traction Control can be switched on or off via the Map Select Switch and functions by analysing throttle input from the rider and the rate at which the engine RPM increases. If the RPM increases too quickly, the EMS registers a loss of grip and reduces the amount of power to the rear wheel, ensuring maximum traction. The Quickshifter can also be engaged using the same Map Select Switch and offers seamless upshifts under heavy load.

Quickshift

The Quickshifter can be activated or deactivated via the Map Select Switch. By interrupting the ignition for a fraction of a second, this allows upshifting while the throttle is fully open without the use of the clutch. The Quickshifter is only active from second gear upwards.

Footrest

Using state-of-the-art computational fluid dynamics, the large footrests are designed for maximum control and to prevent mud from building up. Additionally, the mounting position brings them inwards, which makes them less susceptible to catching on the ground through deep ruts.

Electric start

Taken from the motocross range, the combined start/stop switch is located on the right side of the handlebar for easy, thumb-operated use. Not only simplifying the starting and stopping of the engine, but the removal of a designated stop only button from the handlebar reduces the risk of potential damage or activation in the event of a fall.

Airbox

With precisely positioned inlet ducts reducing air flow deformation, the airbox ensures unrestricted airflow with maximum filter protection. The Twin Air filter is mounted onto a cage designed to offer accurate installation and can be easily accessed without tools by removing the left side panel.

Factory front wheel 1.6x21"

Engine brace set

Lock-on grip set

Skid plate with linkage protection

Factory Racing front wheel 1.6x21"

Factory Racing frame protection set

Radiator protection

Progressive handlebar damping system (PHDS)

Factory rear wheel 2.15x19"

Factory Racing rear wheel 2.15x19"

Flame brake disc

ProTaper handlebar

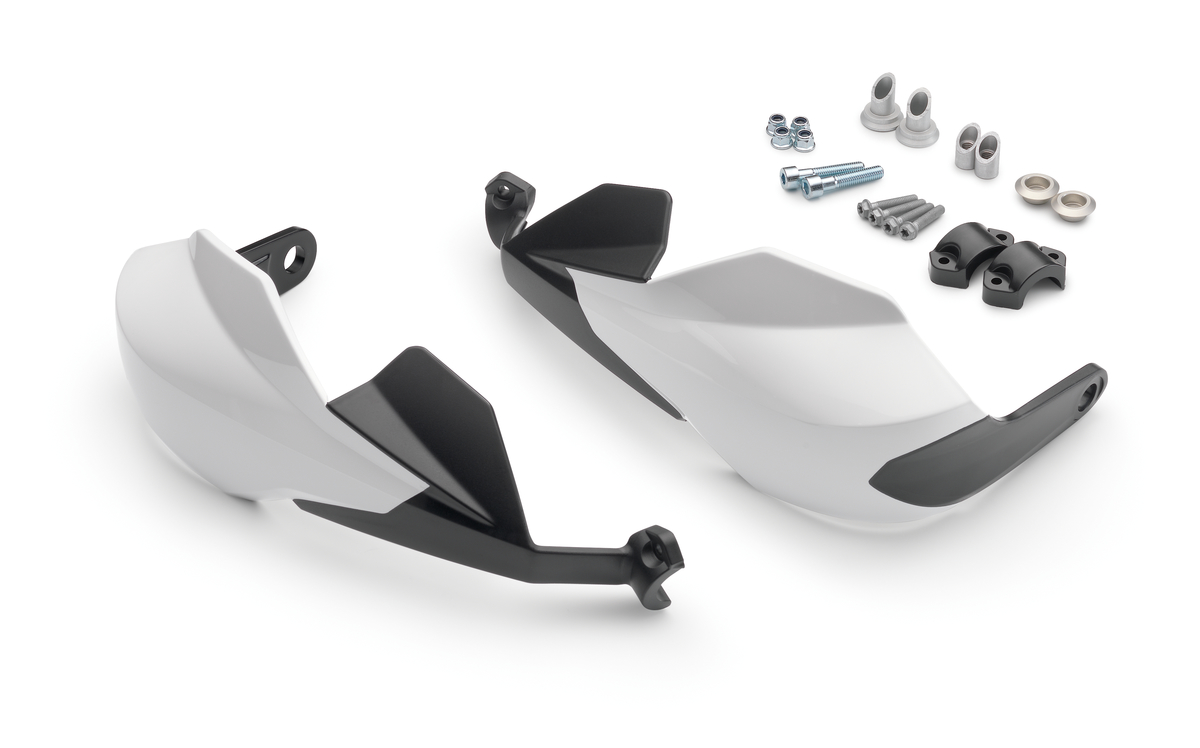

Handguard kit

Factory Racing seat